F

ocus on environment

and savings increased

across all industry

sectors the past few years,

driving innovative solutions

meeting new challenges and

satisfying sophisticated cus-

tomers’ needs. These market

trends have been reflected in

Rexnord’s latest product offer-

ings within their Engineered

Sustainability™ program. This

program is designed to pro-

vide not only reliable products

but system solutions that help

customers meet their environ-

mental targets.

What is Engineered

Sustainability?

Sustainability is the capacity to

endure. Engineered Sustain-

ability by Rexnord is a product

program to help you design du-

rable conveyor systems with

components that guarantee op-

timal product handling without

compromising the ability to meet

targets on safety improvement,

increased productivity, water re-

duction and energy savings.

Maximize safety

In any working environment,

safety comes first. Rexnord’s

Engineered Sustainability pro-

gram will help improve conveyor

system safety with products

that require no external lubrica-

tion and feature closed chain

surfaces for minimized noise

levels.

Optimize Productivity

Conveyors have become the

critical connection between ma-

chines providing optimal product

flow and the required buffering

capacity. Reliability and durabil-

ity of the conveyor components

determine total uptime and cost

to keep the line performance at

required levels. Rexnord’s En-

gineered Sustainability program

will help upgrade conveyors to

increase productivity by using

state-of-the-art designs and ma-

terials for the chains and compo-

nents.

Minimize Water

Conveyor systems in high-speed

beverage filling lines tradition-

ally use a lot of water for ex-

ternal lubrication (required for

low-friction and constant cooling

of high-speed corner tracks).

Rexnord’s Engineered Sustain-

ability program helps to reduce

or completely eliminate external

lubrication and additional waste

water collecting on equipment,

with products that are suitable

for “dry running” at high-speeds.

Reduce Energy

An average beverage filling

and packaging line typically con-

tains around 80 - 100 convey-

ors that have individual drives.

The required power to drive

each conveyor is determined

by factors such as: weight, con-

veyor layout and friction be-

tween various contact surfaces.

Rexnord’s Engineered Sustaina-

bility program will help with state-

of-the-art material combinations

to provide the lowest friction at a

constant level, resulting in direct

energy saving on each conveyor.

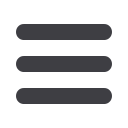

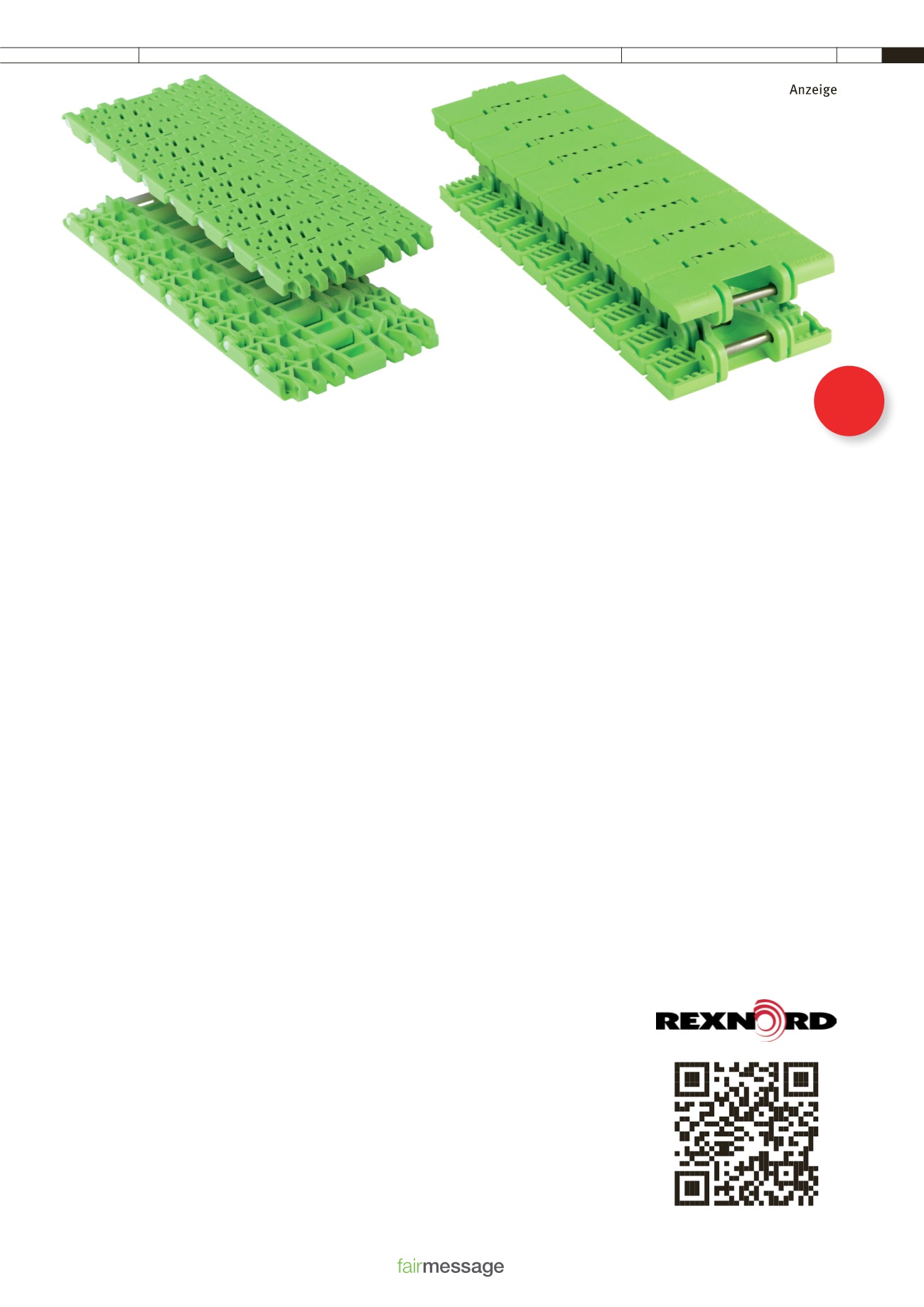

The concept of Engineered Sus-

tainability underpins all products

that Rexnord will show at Inter-

pack 2017. Existing and new

customers may get a first-hand

experience of the innovative

features. The display will include

the Dry-PT™, TableTop

®

and

MatTop

®

Chains, proven to be

the first plastic chain material to

provide the required low friction

against PET on a constant level

over time, where other plastic

chain materials always show a

permanent increase of friction

level after hours of running. An-

other product to be seen at the

Interpack is the Rexnord 1005

XLBP Series MatTop, ideal for

pack conveyors that require a

low backline pressure. This de-

sign sets a new standard for the

beverage industry.

Company Profile

Rexnord TableTop & MatTop

conveyor chains are the product

of choice for a diverse variety of

businesses, including bottlers,

poultry processors, can manu-

facturers even the auto industry.

Through the years, Rexnord has

been responsible for techno-

logical advances in the design

of conveyor chains and associ-

ated conveying components.

Our dedication to new product

development is evidenced by the

breadth and depth of our product

lines. Industries that move prod-

uct from point A to B, in virtually

any category from small parts,

to large industrial products, to

high-speed bottling, to dry food

products and even car washes

rely on Rexnord conveying prod-

ucts. Delicate conveyor products

up to heavy-duty certifications,

they know every chain stamped

with the Rexnord brand has un-

dergone extensive research and

quality testing to ensure your

conveying needs are met with

the most economical, efficient

and reliable means possible.

Focus on environment and savings increased

Engineered Sustainability

Ausg.Nr._06/2017

21

Hall 13

Booth B64

www.rexnordflattop.com