6

Ausg.Nr._06/2017

packaging solutions

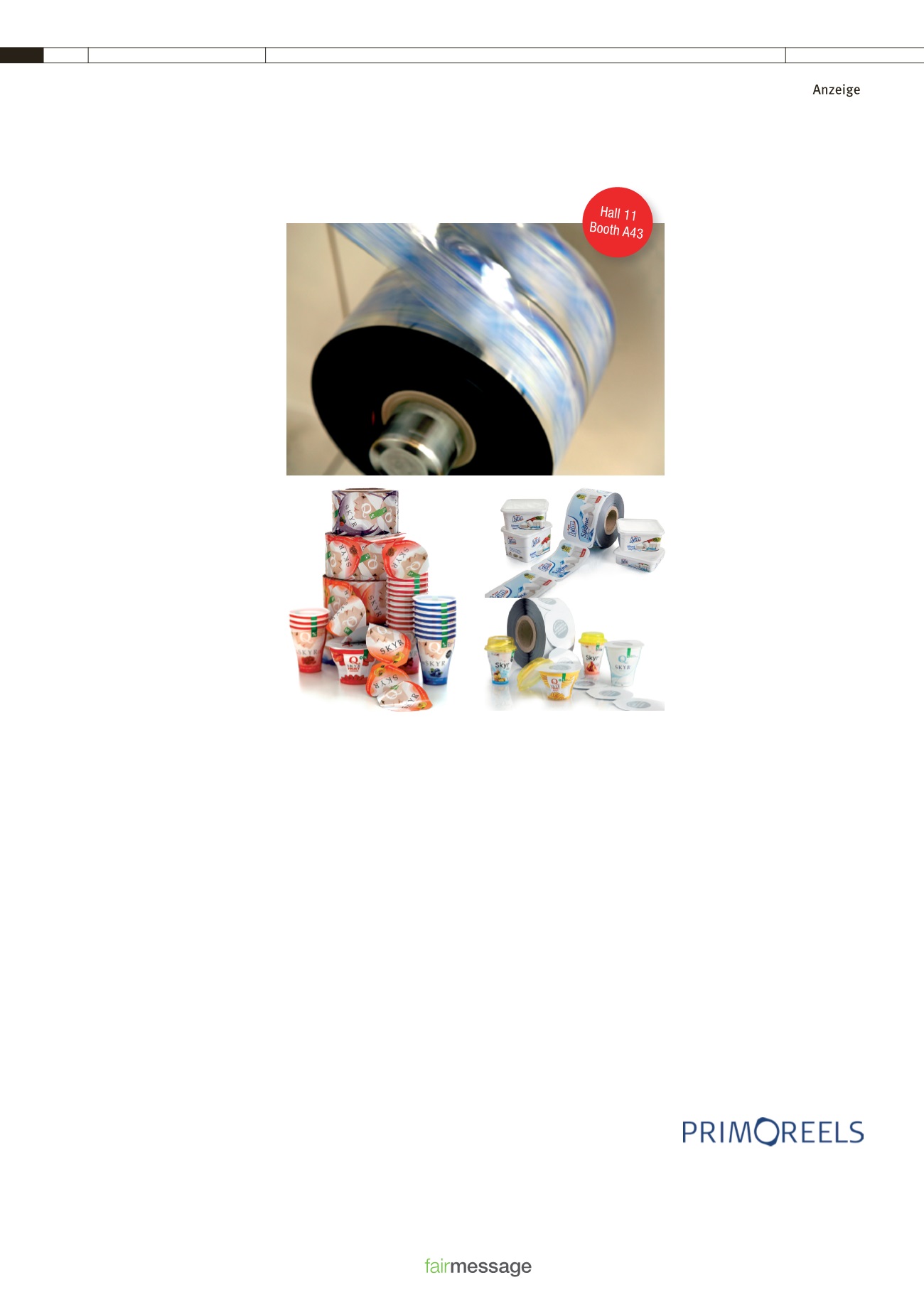

P

rimoreels A/S has be-

come an established

partner for manufactur-

ers in the dairy sector and the

water/juice industry. With the

constant introduction of new

products and battle for shelf

space at retail, our solutions

help our customers stand out

with high-quality graphics and

long shelf-life performance, that

is able to compete with the tra-

ditional thicker Alu die cut lids.

Our plastic solutions have ena-

bled customers to forego expen-

sive and wasteful over capping,

and in this way bring the dairy

packaging to next level in terms

of efficiency and lower total cost.

Primoreels

®

flexible packaging

solutions have fastly gained a

reputation for timely, high-qual-

ity, innovative lidding solutions

that satisfy our customers.

Primoreels A/S was founded in

year 2008, but has its roots from

a filling machine company with

more than 60 years of experience

within the dairy industry. The first

product introduced to the market

was a membrane for the produc-

tion of UF feta cheese, which

enabled the further development

of a lidding system which offers

unparalleled advantages to dairy

product manufacturers whom tra-

ditionally are using ALU/PET die

cut lids or roll-stock solutions.

Primoreels

®

system

The unique Primoreels

®

system

is already installed in numerous

high capacity machines through-

out the world, and further devel-

opment has allowed Primoreels to

retro-fit our stand-alone units to

existing Inline machines as well

as Round table machines, to sig-

nificantly enhance their efficiency

and hygienic security level in the

production. This comes with a

small investment to the existing

filling machine, which runs with

preformed cups and die-cut/roll-

stock solution. Switching lidding

system to a Primoreels solution

will be done in max. 4 days - on

site - and the existing machine

can be of any brand and size.

Each machine unit is tailor-made

and has its own dedicated touch-

screen panel and controls, thus

making them truly independent

units without interfering with the

current PLC or other on the filling

machine. The simple instalment

creates the perfect interaction be-

tween machine and foil material.

Compared to regular die-cut PET

and Aluminium lids, Primoreels

®

PET lids are the new great alter-

native – cost efficient and with

a minimum of carbon footprint.

Primoreels lids comes in thinner

materials than regular die-cut

lids, and therefore it’s expected to

create savings for our customers

all around the world.

Materials can be run as thin as

in 23 microns, and the reels con-

tains as much as 60,000 lids per

reel. Furthermore, it possible to

obtain exceptionally high print

quality on the ultra-smooth lid

surface. Other obvious benefits

include UV-C sterilised lids, which

eliminate contamination and in-

crease shelf life.

Membrane for UF feta production

For the production of Ultra filtrat-

ed (UF) Feta cheese also known

as “Suzme Peynir” in Turkey or

“Shabnam” in Iran, Primoreels

has developed a membrane made

of a white voided OPP film with

opacity and whiteness.

By replacing the traditional per-

meable membrane with a special-

ly developed impermeable mem-

brane Primoreels has radically

simplified the production process

of UF white cheese.

Salting of UF cast cheese using

permeable membranes is a cum-

bersome process that requires

turning the containers twice.

Primoreels has conceived a two-

part solution comprising:

• a special impermeable mem-

brane whose properties ensure

that containers with cheese

no longer need to be turned in

the middle of the manufac-

turing process. The imperme-

able membrane is placed on

the coagulated cheese, salt is

dosed on the membrane,

and the containers may then

be sealed and placed into the

fermentation room in an up-

right position.

• a new type of dispenser for the

membranes that eliminates the

significant cross-contamination

risks during handling of the

membranes.

The membranes are produced

and dispensed in reels with-

out the endless strips of foil

ever being touched by human

hands. Moreover, they pass a

UV treatment device before

being dispensed on the cheese

curd.

The reels with membranes

will typically have enough

units to keep the production

running for up to 8 hours.

The need for constant refilling

of membranes of the machine

is thus removed.

The inline approach to the pro-

cess of filling, coagulation, cut-

ting and packaging performed in

a flow, under ultra-clean condi-

tions, is the safest and most effi-

cient method on the market.

Primoreels enables to cut the

cheese in the containers be-

fore placing the impermeable

Primoreels

®

membranes in the

containers. The process also

makes it possible to add herbs,

oils and the like to the cheese.

For further details of Primoreels’ latest innovative lidding products and services visit: www.primoreels.comPrimoreels

®

- »The lidding system of the future« -

Cost efficient and reliable