Ausg.Nr._06/2017

11

die-cutting machines

B

erhalter – Switzerland's

leading manufacturer of

high-performance die-

cutting machines – is present-

ing a unique technology at Inter-

pack exclusively for embossing

lids on the sealing rim area.

Berhalter makes the difference

Berhalter will be presenting the

newest generation of high-per-

formance die-cutting machines

at Interpack in Düsseldorf, along

with trendsetting innovations,

which Berhalter AG is pioneering

worldwide.

The first of these, the SMARTem-

bosser™ is the logical evolution

for pre-cut lids. As the name says,

the SMARTembosser™ is a smart

way to produce embossed lids.

This by Berhalter patented system

is unique and offers fantastic op-

portunities for rim-embossing,

logo-embossing and de- emboss-

ing of pre-cut lids. The SMARTem-

bosser ™ makes every lid special

and gives additional technical

advantages.

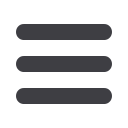

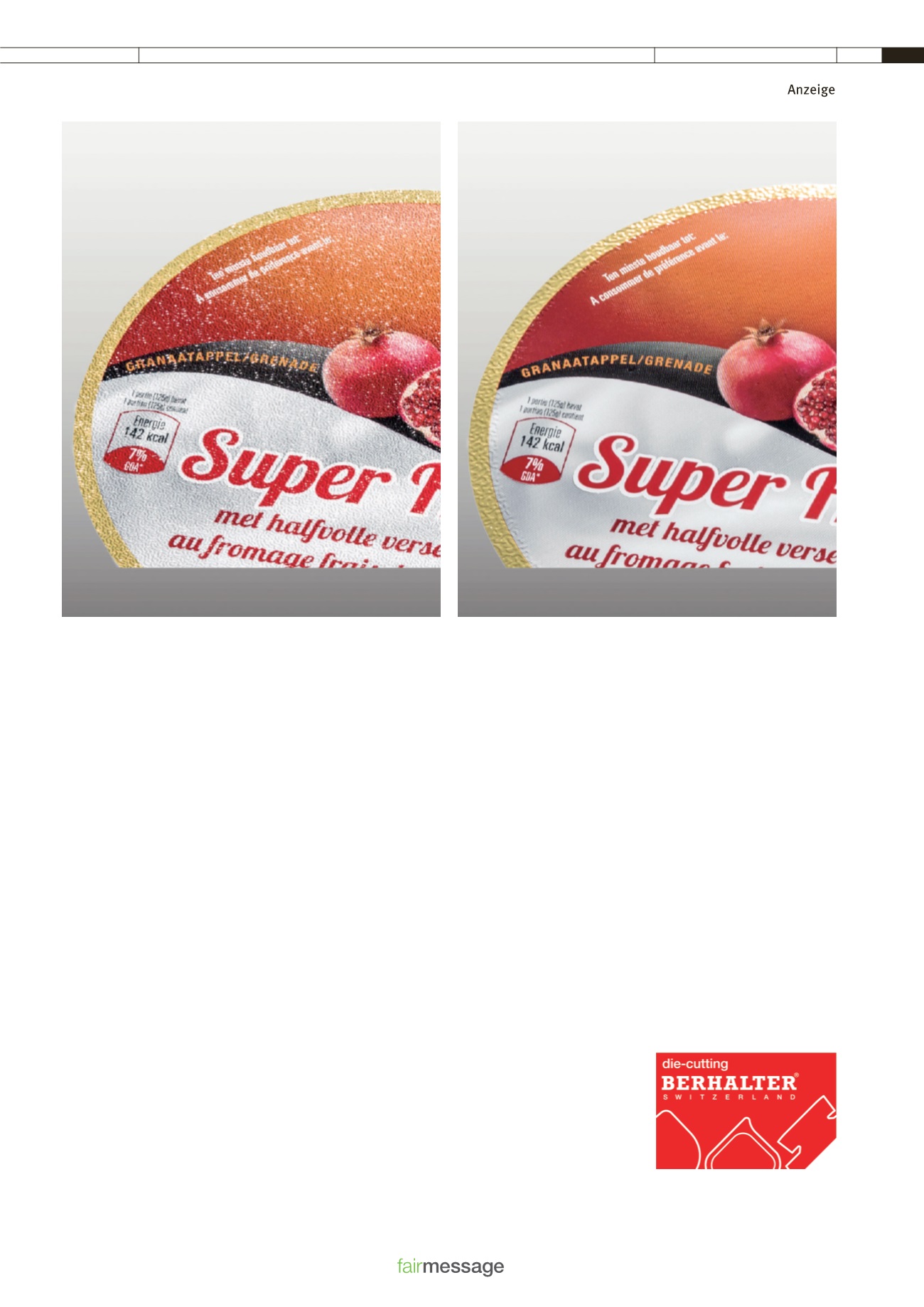

With the application rim-emboss-

ing (embossing is done only in the

sealing rim area) the lid is shining

brighter and greatly enhances the

clarity of color edges. It allows the

printing of considerably smaller,

yet readable lettering, which is

important for product placement

as well as for the food facts re-

quired under food regulations.

Last but not least the SMARTem-

bosser™ for rim embossed lids

can influence the productivity

of filling and sealing machines

enormous.

The application logo-embossing

and de-embossing gives our cus-

tomers the opportunity to pro-

duce non-printed pre-cut lids with

high-lighting a brand logo, sign

or writing.

Using the patented Berhalter

SMARTembosser ™ technology,

lids can be printed with intense

color as well as more space for

graphics and product information

can be achieved – pre-cut lids

never looked so brilliant.

The mark of flexibility

Die-cutting is a piece in the com-

plete supply chain of a final prod-

uct. But nor the less it decides

significantly about success. What

die-cutting solution you choose

decides about appearance of the

product, sustainability, quality as

well as efficiency.

Over the last few years, BERHALTER

has reacted continuously and

highly flexible to increasing mar-

ket demands and has introduced

a number of innovations to the

market. Alongside its capacity for

constant innovation, BERHALTER

is synonymous with the produc-

tion of efficient and customer-

oriented die-cutting systems.

We specialise in the manufactur-

ing of user-friendly but high pro-

ductive die-cutting machines.

This applies for flat packaging

lids out of aluminum or polyes-

ter, such as Nestlé yoghurt lids,

as well as for packaging lids with

relief impressions, like Phila-

delphialids for cheese spread.

Deep-drawn aluminum lids as

those used for pet food like Sheba

or Cesar enhances the extensive

range of product opportunities.

But BERHALTER die-cutting ma-

chines can also be used to pro-

duce paper labels, e.g. on beer

bottles and labels for IML applica-

tions, such as those on Starbucks

coffee cups.

We have the unique possibility to

supply die-cutting machines and

tools according to the specific

market demand.

Come visit us at Interpack,

Hall 11C76!

BERHALTER – the number one in die-cutting www.berhalter.comEmbossed lids never looked so brilliant